Designing Efficient Mass Notification Systems (MNS) for Industrial Sites and Power Plants

ATI Systems provides site surveys that determine the status of current MNS and this is accomplished by

analyzing data such as site layout, machinery noise, and operating conditions.

This data is then input to an in-plant acoustics computer model. The computer model calculates the noise levels generated by plant

equipment and alarm system sound levels, thereby enabling concise and accurate evaluations of system

performance.

Machinery Noise Levels

Noise generated by machines can heavily alter the effectiveness of alarm systems. Machines that would be

major noise sources are identified, and their mechanical data such as operating power, speed, flow rate,

and basic mechanical configurations are recorded.

This data is used to calculate the sound levels of each machine. Empirical equations relating to sound

power to the ratings and configurations of machines are used for the calculations.

With the sound power level estimations for every machine calculated, the resulting sound pressure level is

calculated based upon the acoustic properties of the surrounding area.

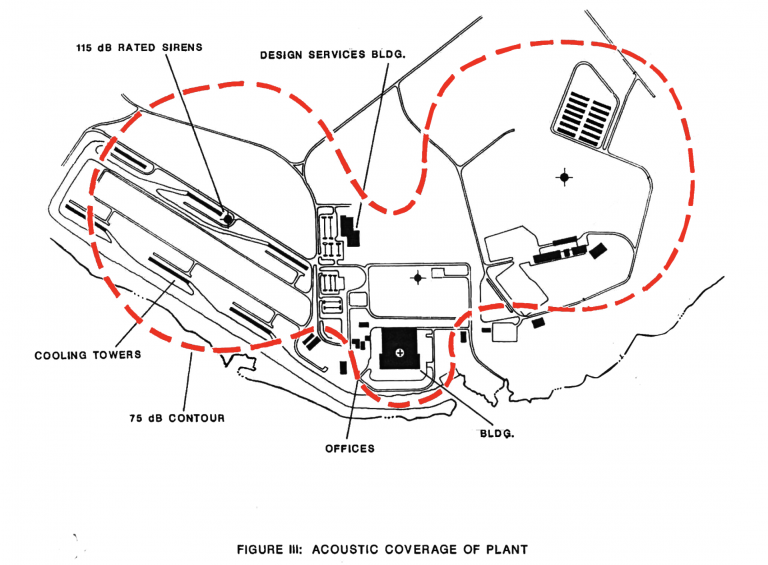

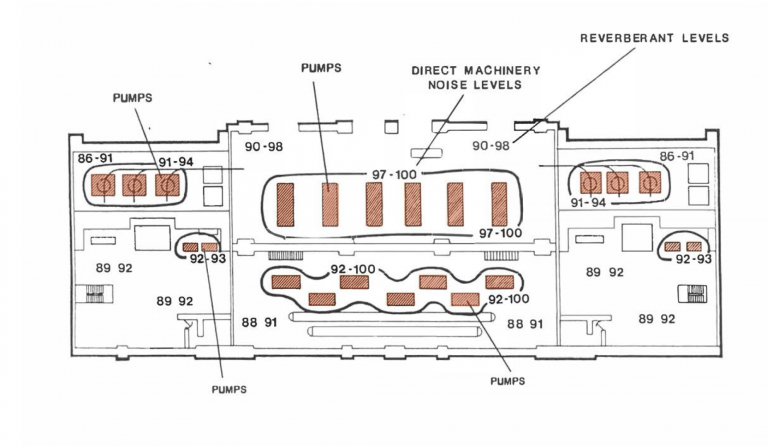

The building characteristics make it necessary to consider not only the sound radiated directly from a

source but also the sound reflection from surrounding walls. Sound undergoing repeated reflections

creates a ‘reverberant’ level that raises the background noise level throughout an area.

Machinery noise levels examples are shown in figures I and II.

In order for an alarm to be effective, its sound level must be greater than that of the background noise (10-

15 decibels (dB) based on the design criteria.) Usually, this can be accomplished simply by using an

appropriate number of sirens.

In some areas, machine noise could be too great for a reasonable number of sirens to overcome. In these

situations, the most cost-effective solution is to use strobe lights to signal the evacuation alert.

Other situations where strobe light alerting could be recommended include very confined areas and areas

with loud machinery that have only intermittent use.

Site Construction in Relation to Acoustics

Buildings may have thick, reflective walls that will acoustically isolate them from the rest of the plant. For

concrete block, poured concrete, and masonry walls, transmission losses of up to 30 to 50 dB can be

expected. This means a sound will be attenuated by 30 to 50 dB as it passes through the walls. With

transmission losses of this magnitude, sound originating from outdoors will have a negligible impact and

background level will depend only on interior noise.

Also, without noisy machinery, levels will be typical of average offices and workshops, falling 60 to 70 dB

A-weighted range. Because these background levels are much less than those of the machinery buildings,

fewer sirens are required.

Enthought permanent buildings have heavy outer walls, many of the interior walls are light enough in

construction that a siren will be effective through them, enabling a single siren to alert several rooms with

minimal sound attenuation.

Optimizing Outdoor Areas

For outdoor sirens to alert workers inside temporary buildings, the signal must undergo a 10 to 15 dB

attenuation as it passes through the walls. Assuming a 15 dB loss, a 75 dB outdoor signal will be adequate

to alert the people indoors. The 75 dB outdoor signal level is a commonly used guideline for designing

indoor/outdoor alerting systems.

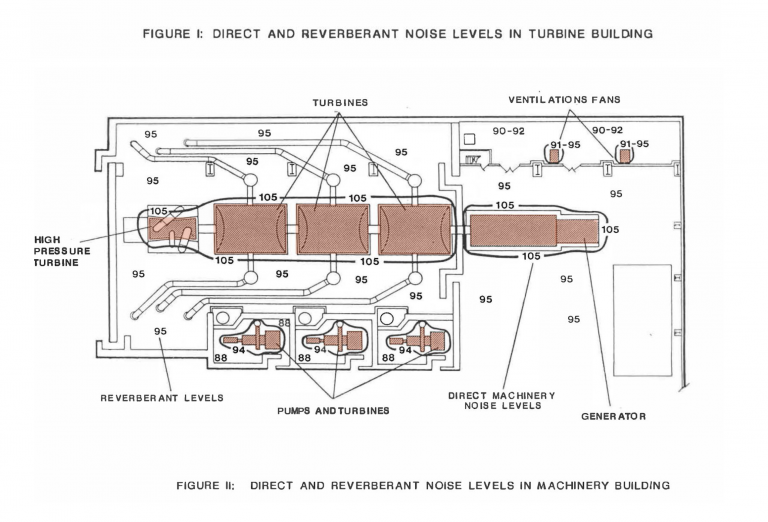

Figure III shows an example site using two sirens rated at 101 dB at 100 feet and two sirens rated at 115 dB

at 100 feet. Using this siren configuration, all of the temporary buildings will be alerted with at least 75 dB

and all of the remaining outdoor areas will be alerted with at least 60 dB.